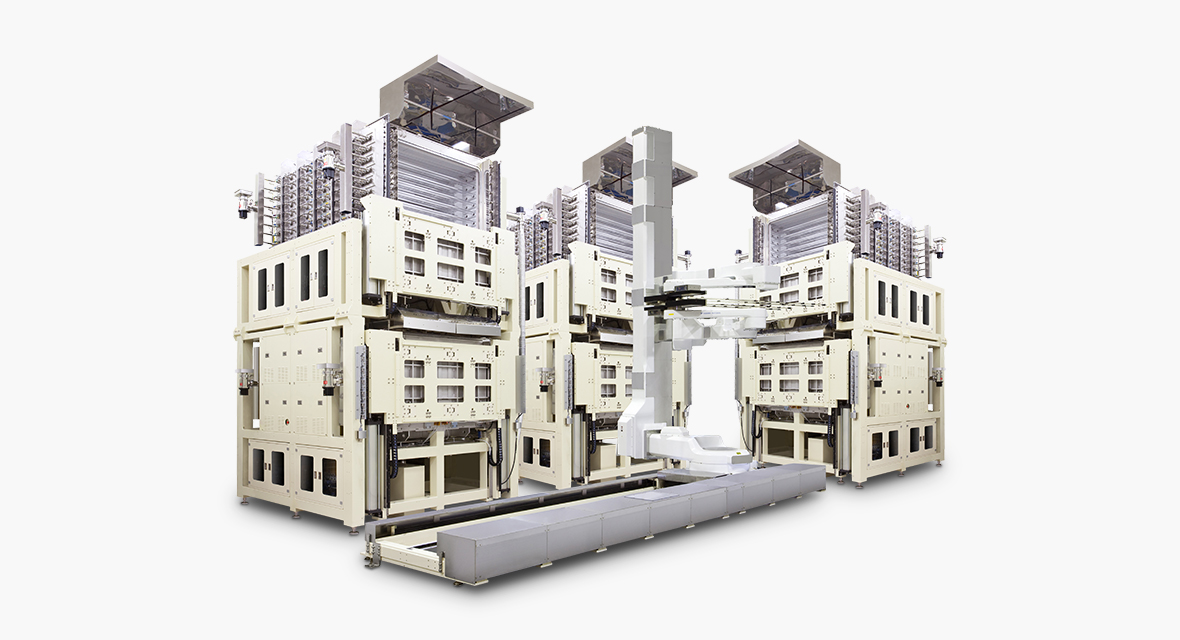

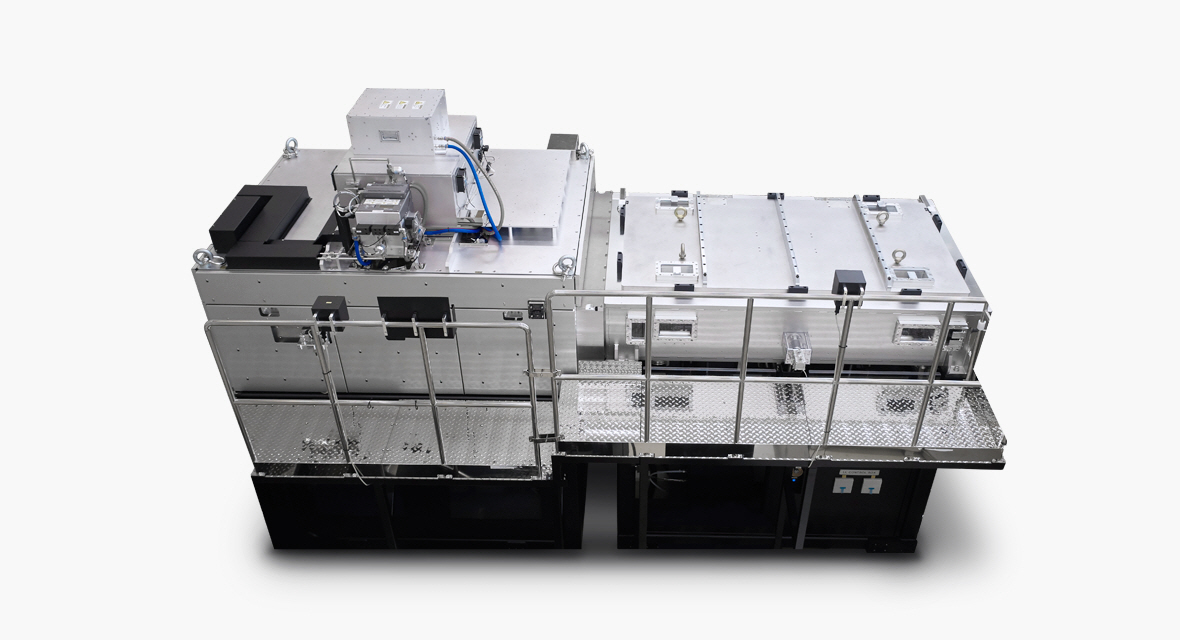

Cryster series 600

Process

Contact anneal

De-hydrogenation

Hydrogenation

Activation

Applications

AMOLED Rigid/Flexible用

LTPS TFT Backplane (Mobile)

Introduction.

Low-temperature polycrystalline silicon (LTPS) equipment specializes in contact anneal, de-hydrogenation, hydrogenation, activation, and other high-temperature thermal treatments in the AMOLED rigid/flexible display manufacturing process.

Technology.

This equipment implements a wide range of temperature from high to low and is capable of optimizing the client’s process requirements. It provides IPS’s original pollution control and precision temperature control, and applies a fast ramp up/down function for high productivity.

Features.

1. Glass size: up to 8G 2. Max. temperature: up to 500℃ 3. Front door specially manufactured to control very high temperature uniformity 4. Technology capable of maintaining and controlling the minimum O2 level 5. Fully open rear door, which is easy to maintain 6. Gas injection system specially manufactured to provide a uniform gas laminar flow for an optimal process 7. Fast ramping process (FRP) which can implement high productivity and a precision process with special technology capable of fast heating and cooling 8. Cooling stage specially manufactured for optimal aligning and fast cooling

Related products

Product and technical inquiries

TEL : 82-31-831-2723 E-mail : fpd@ips.co.kr